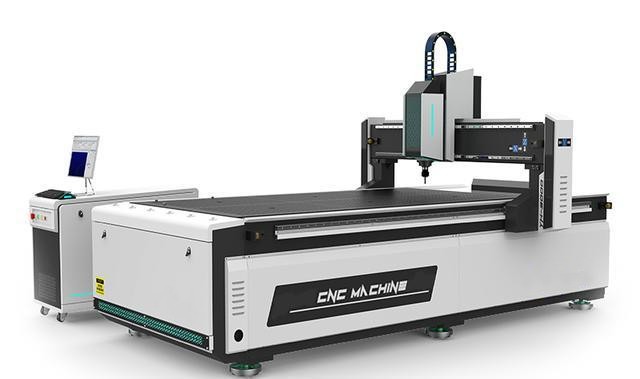

Five points you must know about the difference between CNC milling machine and engraving machine

Difference between CNC milling machine and engraving machine

1. What are the main differences between CNC engraving and CNC milling?

Both CNC engraving and CNC milling adopt the principle of milling. The main difference lies in the diameter of the tool used. The diameter range of the tool commonly used for CNC milling is 6-40mm, while the diameter of the tool used for CNC engraving is 0.2-3mm.

2. Can CNC milling only be used for rough machining and CNC engraving only be used for finish machining?

Before answering this question, let's first understand the concept of process. The amount of rough machining is large while the amount of finish machining is small, so some people habitually regard rough machining as "heavy cutting" and finish machining as "light cutting". In fact, rough machining, semi finish machining and finish machining are technological process concepts, which represent different processing stages. Therefore, the exact answer to this question is that CNC milling can do heavy cutting and light cutting, while CNC engraving can only do light cutting.

3. Can CNC engraving be used for rough machining of steel materials?

Whether CNC engraving can process a certain material depends mainly on how large a tool can be used. The cutter used in CNC engraving determines its maximum cutting capacity. If the mold shape allows the use of tools with a diameter of more than 6mm, it is strongly recommended to use CNC milling first, and then use the carving method to remove the remaining materials.

4. Can an increase head be added to the spindle of the CNC machining center to complete engraving?

Cannot complete. This kind of product appeared in the exhibition two years ago, but it was unable to finish carving processing. The main reason is that the design of CNC machining center has considered its own tool range, and the overall structure is not suitable for engraving. The main reason for this wrong idea is that they mistook the high-speed motorized spindle as the only feature of the engraving machine.

5. CNC engraving can use tools with very small diameters. Can it replace EDM?

It cannot be replaced. Although engraving reduces the range of cutter diameter for milling, small molds that previously could only be machined by EDM can now be machined by engraving. However, the length/diameter ratio of engraving tools is generally about 5:1. When using a small diameter tool, only a very shallow cavity can be machined, while the EDM process has almost no cutting force. As long as the electrode can be manufactured, the cavity can be machined.